Industry 4.0 refers to the intelligent connectivity of machines and processes in the industry with the help of information and communication technology. There are many ways for companies to use intelligent connectivity. The possibilities include, for example:

• Flexible Production: Many companies are involved in the manufacturing of a product, who contribute step by step in the development of the product. Digital connectivity can make these steps better coordinated and the utilization of the machines better planned.

• Convertible factory: Production lines will be built in modules in the future. They can be quickly assembled for a task. Productivity and efficiency are improved, individualized products can be produced in small quantities at affordable prices.

• Customer-centric solutions: consumer and producer move closer together. The customers can design products according to their wishes by themselves - for example, elements of sneakers can be designed and adapted to the individual foot shape. At the same time, smart products that are already delivered and in use can send data to the producer. With the usage data, the producer can improve his products and offer the customer novel services.

• Optimized logistics: Algorithms calculate ideal delivery routes, machines independently report when they need new material - the smart connectivity enables an optimal flow of goods.

• Use of data: Data on the process of production and the condition of a product are combined and evaluated. Data analysis provides guidance on how to make a product more efficiently. More importantly, it's the foundation for completely new business models and services. For example, lift manufacturers can offer their customers "predictive maintenance": elevators are equipped with sensors that continuously send data about their condition. Wear can be detected and corrected before it leads to the failure of the elevator.

• Resource-efficient circular economy: products are considered data-driven over their entire life cycle. Even in the design, it is determined in which form the materials can be recycled.

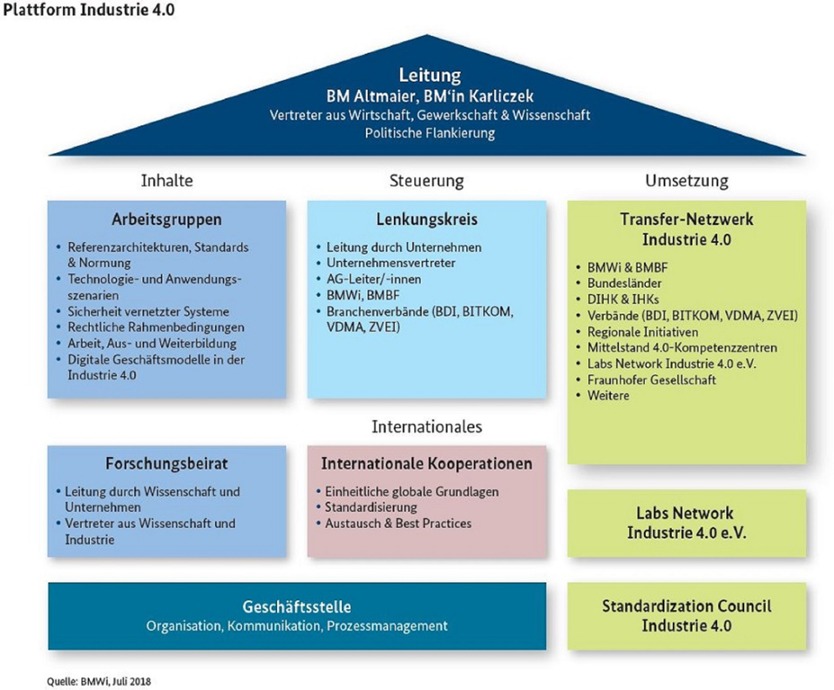

Implementing Industry 4.0 is a complex project: the more processes the economy digitizes and connects, the more interfaces are created between different players. Uniform norms and standards for different industrial sectors, IT security and data protection play an equally central role as the legal framework, the changes in education and work, the development of new business models and the necessary research. All these topics are dealt with by the experts of Plattform Industrie 4.0. For people who want to understand what Industry 4.0 is, the Plattform and its main players are the important drop-in centers they should visit.

The Plattform Industrie 4.0 was founded in 2013 as a joint project of the German business associations BITKOM (The Federal Association for Information Technology, Telecommunications and New Media), VDMA (German Engineering Federation) and ZVEI (Central Association of electrical and electronics industry) for the further development and implementation of the future project "Industry 4.0", founded as the high-tech strategy of the Federal Government. In 2015, the platform was expanded to include stakeholders from companies, associations, trade unions, science and politics. At the beginning of 2019, more than 350 players from more than 150 organizations are actively involved in the platform. The focus of the work of the platform is to bundle the expertise in relation to Industry 4.0 and to make it available to German companies, especially SMEs.

The platform is managed by the following players:

• Federal Ministry of Economics and Energy

• Federal Ministry of Education and Research

• Deutsche Telekom AG

• Federation of German Industries

• IG Metal

• SAP SE

• Fraunhofer Society

• Siemens AG

• Festo AG

This steering group is subordinated to six working groups. The working group “Reference Architectures, Standards and Standardization” develops and negotiates necessary standards and standardizations for Industry 4.0. The Research and Innovation working group identifies research needs in the field of action and proposes implementation recommendations to the stakeholders. The Group “Security of Networked Systems” develops methods and concepts to ensure the security in the Internet of Things. The “Legal Framework” working group has set itself the goal of determining to what extent the current right to Industry 4.0 applies. The working group “Work, Education and Training” deals with how cooperation between people and machine can be designed. The focus of the sixth working group “Digital Business Models in Industry 4.0” is on the basic prerequisites and operating principles of digital business models in Industry 4.0.

The goal of the platform Industrie 4.0 is to promote the digital transformation in production. The idea behind the platform is the pooling of expert knowledge, preparation of recommendations for action and the initiation of uniform standards. The findings are to be discussed in a dialogue between companies, science and politics and then made available to medium-sized companies in particular. Germany as the economy and production location should profit as a whole.

In general, Plattform Industrie 4.0 tackles these and similar questions:

• How can the production location Germany with Industry 4.0 further increase its competitiveness and become the leading factory supplier for Industry 4.0?

• What role can Germany play in defining standards?

• How can the working environment be shaped with Industry 4.0 for the benefit of the people?

At the Hannover Messe 2019, Plattform Industrie 4.0 and its partners presented the mission statement 2030 for Industry 4.0, which emphasizes sovereignty, interoperability and sustainability as central guidelines for global, open, digital ecosystems. The platform Industry 4.0 shows its current work status in annual progress reports.

© Plattform Industrie 4.0

渤锐斯谷企业家精英国际俱乐部恭祝大家: 新年快乐!大发利市! H... 详情

2017年5月25日,由企业家精英(国际)俱乐部、上海嘉定区经济委员... 详情

企业家精英国际俱乐部旨在弘扬中国精神,以推动“商业正气、回报社会、造... 详情

随着国内外精英企业家的加入,企业家精英(国际)俱乐部日益发展壮大。在... 详情

为了加快工业领域人才培养的步伐,满足社会不断增长的对工业领域人才的迫... 详情

2017年8月6日,应美国密西根州长Rick Snyder(里克.斯... 详情

刚才这个举手的动作我忽然想到人民代表大会,所以今天看到大会的这八个字... 详情

制造业一直是本行,近几年随着智能网等变化当中制造业有了很大的冲击,对... 详情